Alfred Kärcher SE & Co. KG is a family-owned company headquartered in Winnenden, Baden-Württemberg. The world market leader for cleaning technology employs more than 13,500 people worldwide. The company is particularly renowned for its high-pressure cleaners.

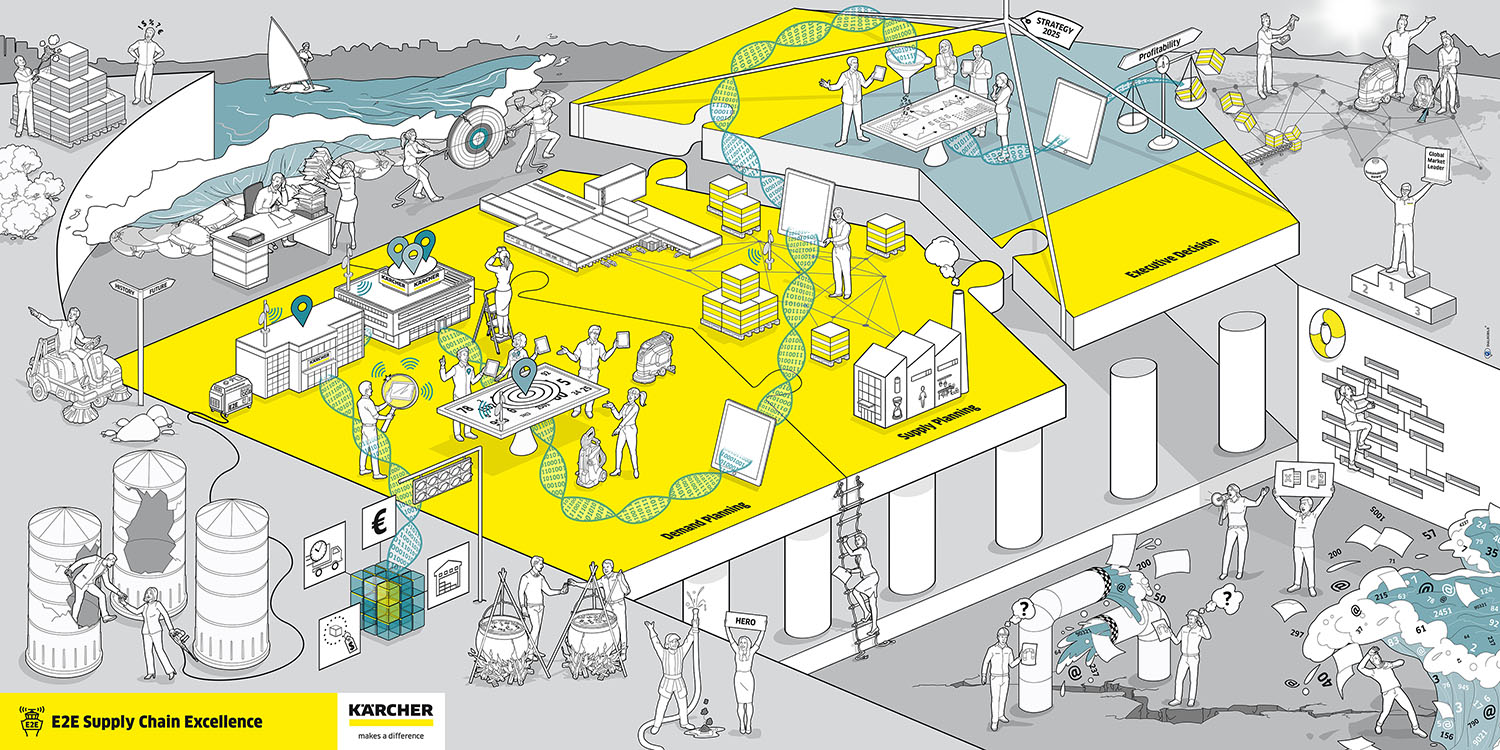

In order to remain the world market leader in the future and to be able to supply customers optimally, Kärcher is constantly working on the optimization of its own supply chain management. The current strategy-relevant “End-to-End Supply Chain Excellence” project involves changes in processes, roles and responsibilities that will affect around 6,000 employees worldwide. In order to guarantee a uniform understanding of all project participants, Kärcher developed the dialog picture of the “E2E Supply Chain Excellence” change project, which was developed by DIALOGBILD accordingly.

The picture visualizes the process of the project as a path, starting from the current Kärcher reality. The viewer is informed about the new supply chain process to be implemented, in which he follows a bridge that leads to the future of Kärcher.

The organisational changes enshrined in it are related and linked by a DNA strand that symbolizes the flow of all relevant data. The business management parameters: requirements, stocks, production volume and location are effectively aligned with one another in the projected target state and are available to the customer efficiently as a Kärcher product "all time, in full". The bridge is supported by a stable Master Data Management foundation and other strategically oriented Kärcher projects. Challenges, fears and concerns are successfully overcome.

A special feature of the development of this dialog picture was that the in-house Kärcher illustration style was adopted. For this purpose, the illustrations were adapted to Kärcher's corporate identity guidelines, from style to colour to line thickness.

SINGLE SCENES AND THEIR MEANINGS

Lack of coordination leads to a wrong planning process of supply and demand.

Historical data cubes – the starting point of our new planning process.

SELECT INFO PACKAGE

SELECT INFO PACKAGE