AUDI AG has one of the most flexible and efficient production systems in the automotive industry: The Audi Production System (APS) is based on the basic principles of stroke, flow, pull and perfection. Audi consistently implements these principles in production and throughout the company. The APS can only work successfully with good cooperation between all business areas along the process chain. As a result, Audi achieves short cycle times, low inventories and high productivity in production with an annual rate of increase of up to ten percent. This Audi production system now has to be implemented in the plant in Mexico in the coming years.

The goal of the dialogue picture is to make the strategy of the Audi production system understandable for all employees. The current situation as well as the challenges and risks should be presented.

The dialogue picture not only shows the entire production process and its interfaces, but also reflects the development and soft goals of the plant:

Where do we come from

What have we achieved?

What characterizes us?

And how do we want to work together?

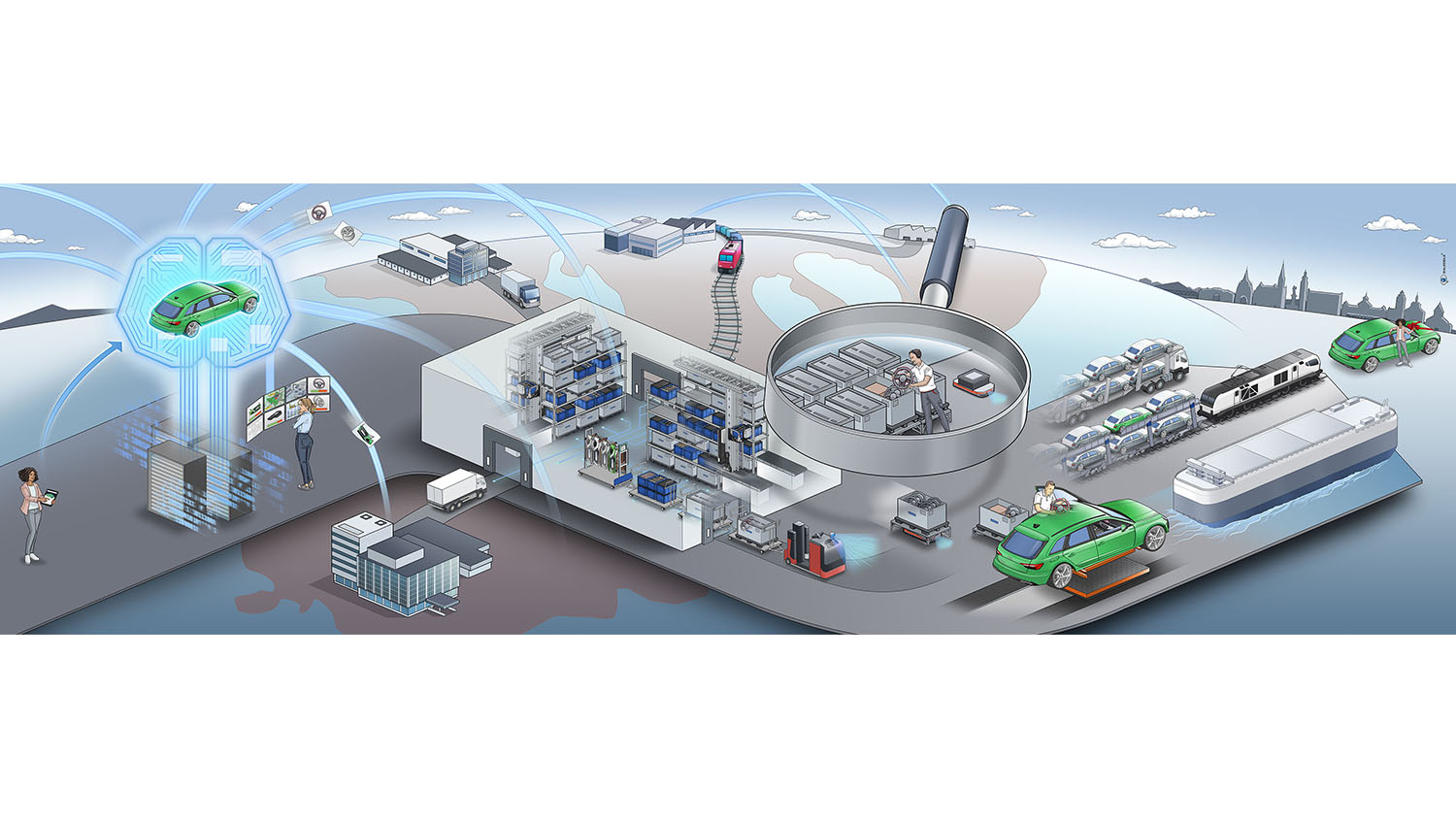

The topics and interrelationships are visible at first glance and are easily understandable from a bird's eye view. The employees find themselves in the individual scenes, which triggers a feeling of belonging. In this way, it is possible to actively involve employees.

The dialogue picture was developed in several web conferences. Together with an illustrator and a consultant from DIALOGBILD and a core team from Audi Mexico, the topics were realized and sketched live. In this way, everyone involved could be actively involved in the development process and had the opportunity to help design the dialogue picture live. Then the dialogue picture was worked out.

The Audi Mexico team provided extensive photo material for this purpose, which enabled important details to be taken into account in the preparation. Particular attention was paid to the vehicle and machine details in production, the heart of the plant. And this is exactly where the dialogue picture should be present for everyone - the dialogue picture is printed in XXL format and hung up in the production hall. This way, employees are reminded of our vision and get one step closer to their vision of the future every day.

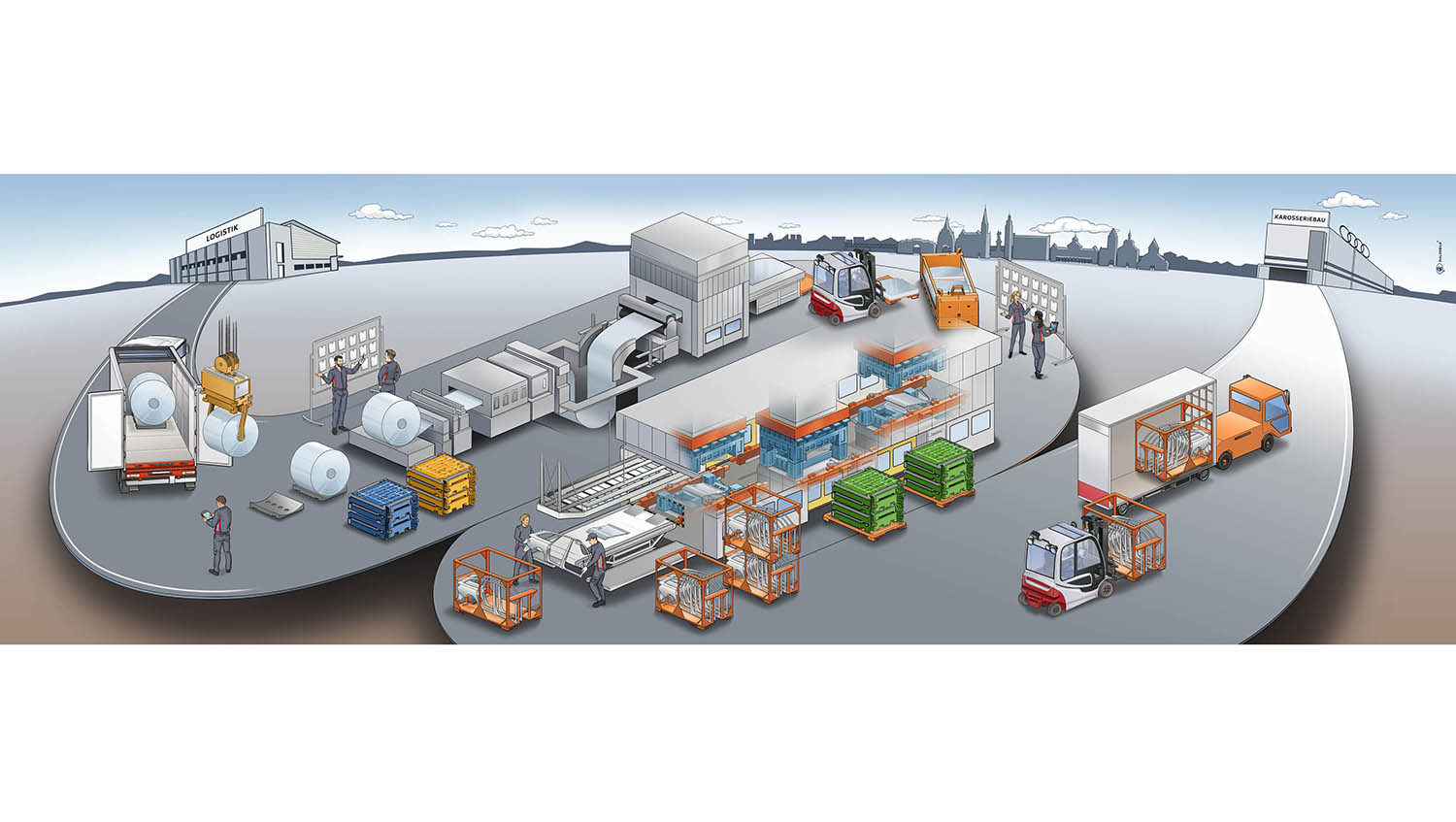

INDIVIDUAL SCENES AND THEIR MEANINGS

Product development is located close to the production and supplies new materials and parts that are brought into production directly from development.

Plug & Play solution thanks to the use of standardized processes and solutions from the Audi modular system.

The Audi plant in San José Chiapa was built within a very short time and now offers jobs to more than 5,200 Mexicans. In just 6 years, the plant has produced more than 500,000 Q5 vehicles. The Audi team is proud of what it has achieved.

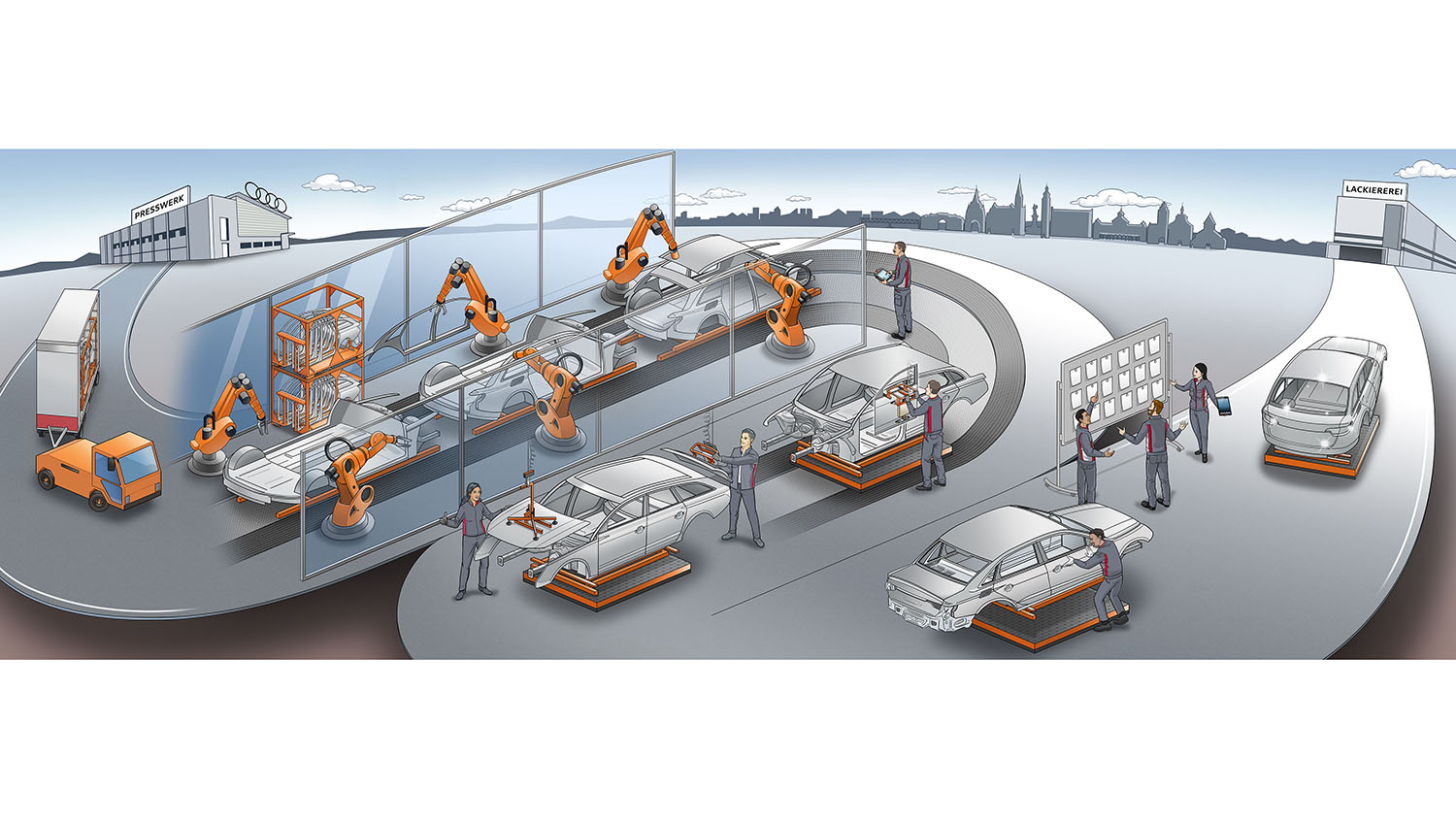

In a campaign with a safety pilot who was doing his lap in the Audi plant, attention was drawn to the issue of occupational safety.

The use of robotics enables workers to adopt an ergonomic posture that makes physical work easier.

Customer feedback is integrated directly into the continuous improvement process.

SELECT INFO PACKAGE

SELECT INFO PACKAGE