AUDI AG stands for sporty vehicles, high-quality workmanship and progressive design. The Audi Group is one of the most successful manufacturers of cars in the premium segment. At its production sites worldwide, Audi stands for "Advancement through technology". Highly qualified employees use innovative logistics processes, modern manufacturing technologies and efficient production systems to set uniform standards within the Audi production system. Each production site meets the highest standards of quality, efficiency and environmental compatibility.

Audi opened the 12th plant in the Audi production network in San José Chiapa, Mexico, on September 30, 2016. After only a short time, the fledgling Mexican Audi plant was already one of the country's most attractive employers. 5,200 people work together here, producing the Audi Q5 premium SUV on an area of 430 hectares. 156,650 locally produced Audi Q5s rolled off the production line here in 2019. At 2,400 meters above sea level, the most modern production facility in the Audi world is also the company's highest-altitude site. The plant has an annual production capacity of 150,000 Audi Q5 models.

THE PROJECT AND ITS DEVELOPMENT

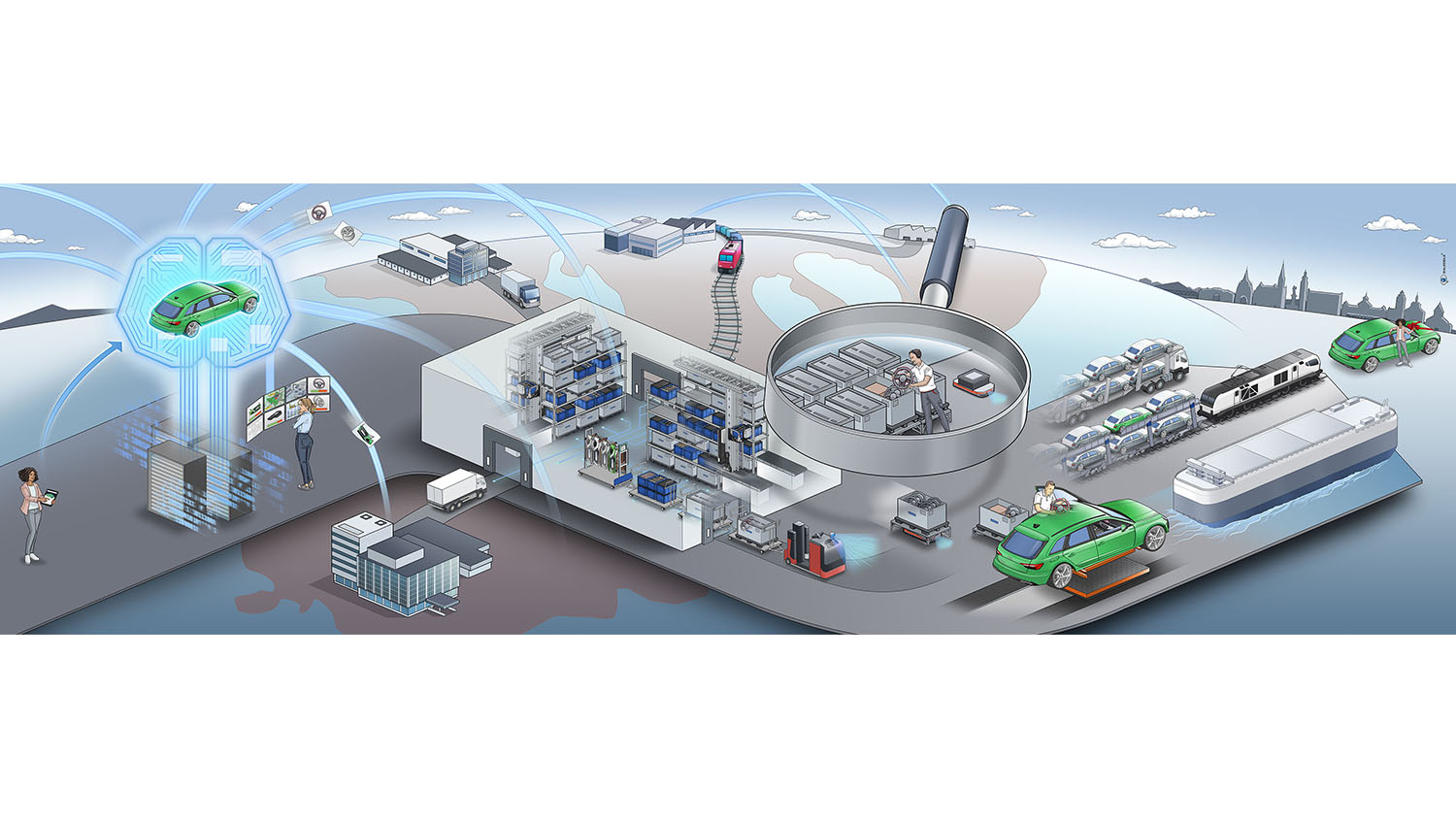

AUDI AG has one of the most flexible and efficient production systems in the automotive industry: The Audi Production System (APS) is based on the fundamental principles of cycle, flow, pull and perfection. Audi consistently implements these principles in production and also throughout the entire company. The APS can only work successfully if all business areas along the process chain cooperate well. As a result, Audi achieves short throughput times, low inventories and high productivity in production with an increase rate of up to ten percent annually. This Audi production system must now be implemented at the plant in Mexico in the coming years.

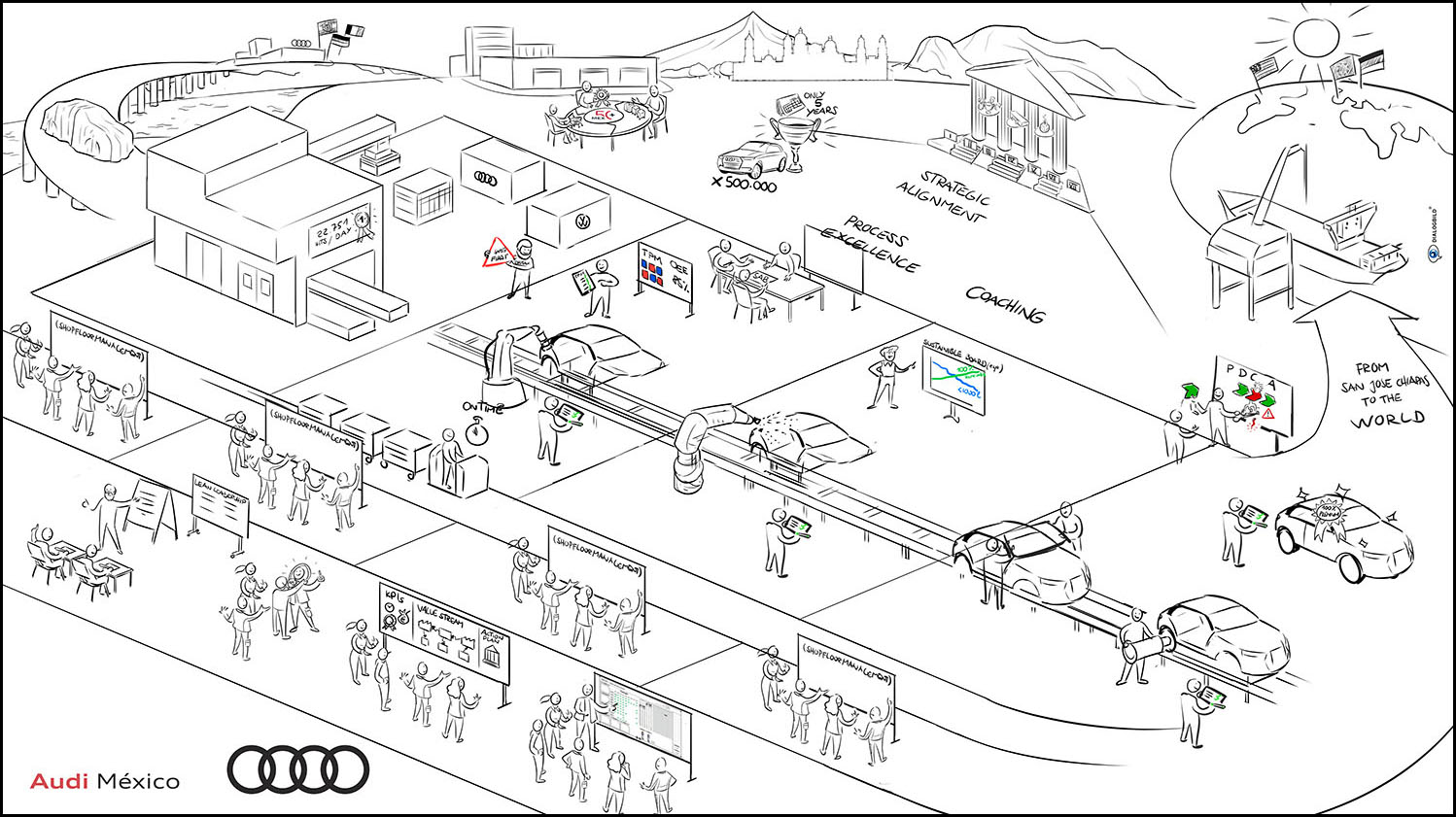

The aim of the dialog picture is to demonstrate the strategy of the Audi production system in a way that all employees can understand. In doing so, the current situation as well as the challenges and risks are to be presented.

The dialog picture not only shows the entire production process and its interfaces, but also reflects the development and soft goals of the plant:

Where do we come from?

What have we achieved?

What distinguishes us?

And how do we want to work together?

The topics and contexts can be grasped at first glance and are presented in an easily understandable way from a bird's eye view. Employees find themselves in the individual scenes, which triggers a sense of belonging. In this way, it is possible to actively involve employees.

The content of the dialog picture was developed in several web conferences. Together with an illustrator and consultant from DIALOGBILD and a core team from Audi Mexico, the topics were developed and sketched live. In this way, all participants were actively involved in the development process and had the opportunity to shape the dialog picture live. The dialog picture was then elaborated.

For this purpose, the team from Audi Mexico provided extensive photographic material, which allowed important details to be taken into account in the development. Particular attention was paid to the vehicle and machine details in production, the heart of the plant. And this is exactly where the dialog picture should be present for everyone - among other things, the dialog picture is printed in XXL format and hung up in the production hall. In this way, employees are constantly reminded of their vision and come one step closer to their image of the future every day.

INDIVIDUAL SCENES AND THEIR MEANING

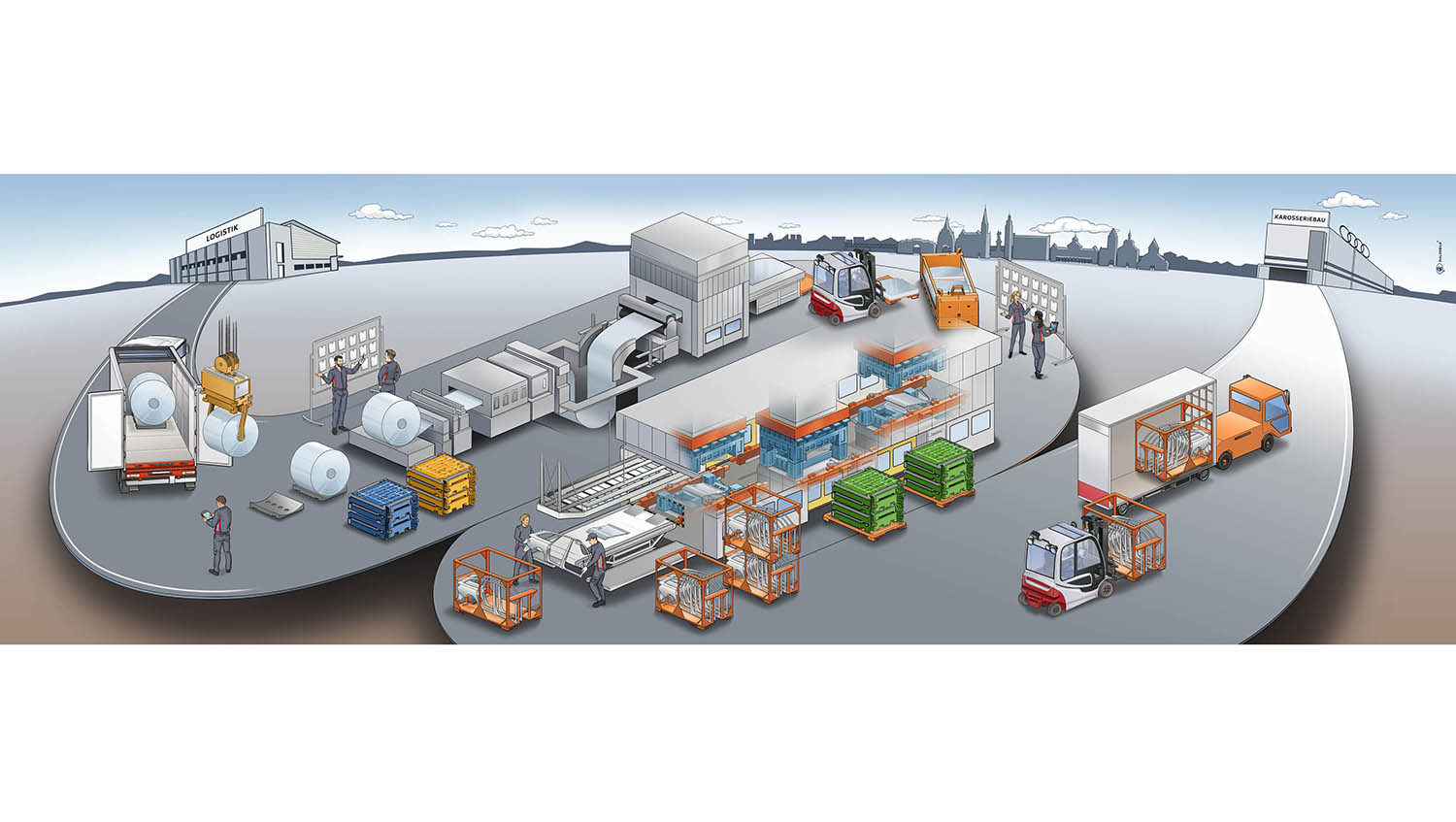

Product development is located close to production and supplies new materials and insert parts that are directly introduced into production by development.

Plug & Play solutions thanks to the use of standardized processes and solutions from the Audi construction kit.

Within a very short time, the Audi plant in San José Chiapa was built and now provides work for more than 5,200 Mexicans. In just 6 years, the plant has produced more than 500,000 Q5 vehicles. The Audi team is proud of what has been achieved.

In a campaign with a Safety Pilot, who made his rounds in the Audi plant, attention was drawn to the topic of occupational safety

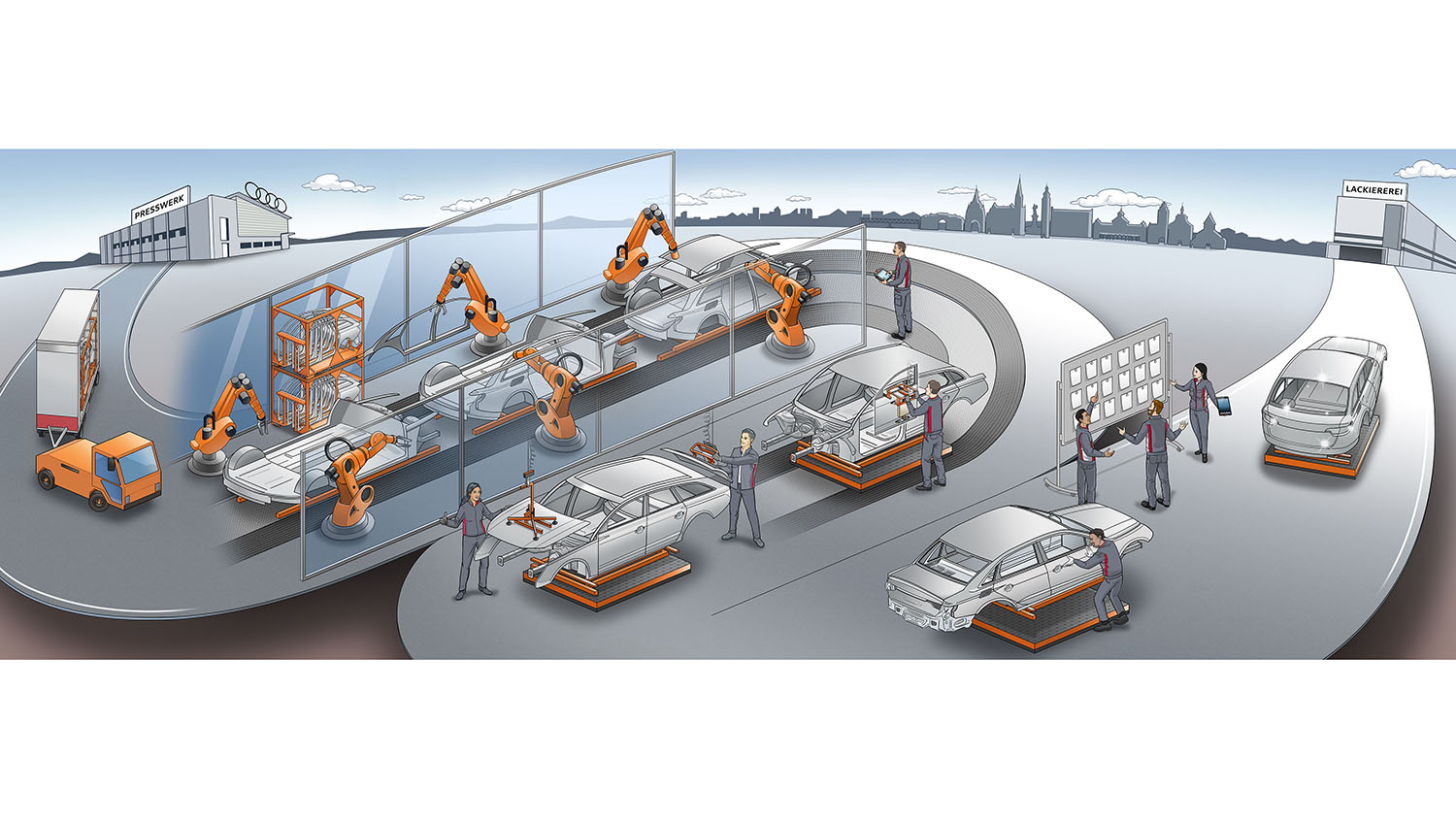

The use of robotics allows workers to maintain an ergonomic posture that facilitates physical labor.

Customer feedback is incorporated directly into the Continuous Improvement Process.

SELECT INFO PACKAGE

SELECT INFO PACKAGE